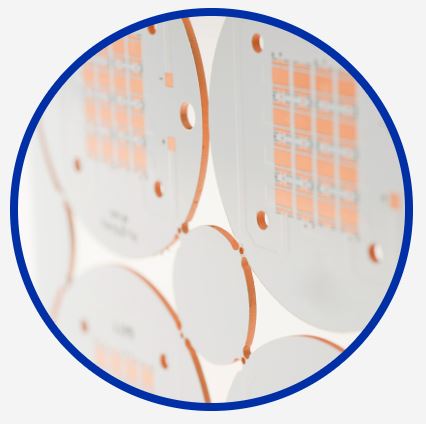

IMS - METAL LAMINATED

Thick aluminum-based substrate, laminated with ED copper foil.

Designed for effective heat dissipation and high electrical insulation.

Our specially formulated polymer ceramic ensures high thermal conductivity, dielectric strength and thermal resistance.

AISMALIBAR’s insulated metal substrates enable processing with standard PCB processes and integrate heat dissipation without additional components and SMD assembly process.

Multilayer

Multilayer PCBs are often required for complex PCBs with denser circuitry.

This combination of multiple layers allows for better functionality and connections.

AISMALIBAR offers various substrates that can be combined to provide unique solutions tailored to your electronic designs.

BOND SHEET

AISMALIBAR offers a range of high-performance thermally conductive foils (thermal prepegs) for various applications in the field of PCBs and MPCBs.

The use of thermally conductive films makes the dielectric layers thermally conductive and ideally suited for dissipating heat from the heat-generating components on the functional copper to the copper layer or heat sink layer on the opposite side.

Thermally conductive foils are available in thicknesses between 80 and 100 µm (3.1 and 4 milli = thousandths of an inch), with a thermal conductivity of 2.2 W/mK or 3.2 W/mK.

Thermally conductive films are used in standard multi-layer lamination processes.

Their high thermal shock resistance, coupled with their high thermal conductivity, guarantees reliable and efficient heat dissipation in heat-critical circuits.

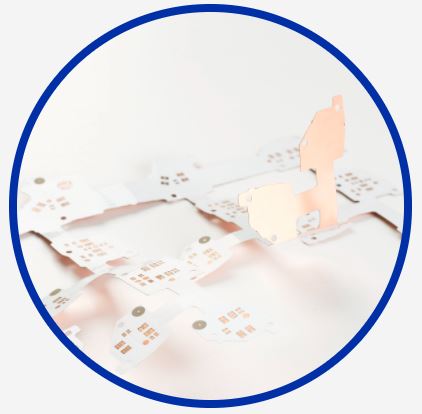

Copper clad laminate

Copper clad laminates consist of an inner layer of prepreg laminated on both sides with a thin layer of copper foil.

The lamination is achieved by pressing one or more layers of copper and prepreg together under high heat, pressure and vacuum conditions.